Daikin Service Checker Type 3 Download

Hello everyone, this is my first post, hope you guys could help me with a problem. I received from my collegue the Daikin Service Checker module Type III and an empty laptop. The Spare Parts Bank is your online resource for parts and service information for Daikin products in the United States and Canada. Click here to download DAIKIN_ALTHERMA on Daikin City. This tool includes selection check based on selected system capacity & entered piping lengths, calculates additional refrigerant charge, system type.

Autopano Giga pro is the most advanced features supported image switching software that makes panoramas creation more efficient and simpler. Autopano giga keygen machine.

Type 3 Software

Also See for VRV

Also See for VRVReference manual - 68 pages

Installation manual - 32 pages

Operation manual - 14 pages

Installation manual - 32 pages

Operation manual - 14 pages

123456789101112131415161718192021222324252627282930313233343536373839404142434445464748495051525354555657585960616263646566676869707172737475767778798081828384858687888990919293949596979899100101102103104105106107108109110111112113114115116117118119120121122123124125126127128129130131132133134135136137138139140141142143144145146147148149150151152153154155156157158159160161162163164165166167168169170171172173174175176177178179180181182183184185186187188189190191192193194195196197198199200201202203204205206207208209210211212213214215216217218219220221222223224225226227228229230231232233234235236237238239240241242243244245246247248249250251252253254255

Basic Training Manual

Advertisement

Also See for Daikin VRV

Related Manuals for Daikin VRV

- Inverter Daikin VRV K Manual(170 pages)

- Inverter Daikin FTK25JV1NB ManualInverter pair (142 pages)

- Inverter Daikin K-Series Service ManualFloor standing (151 pages)

Daikin Service Tools

- Inverter Daikin RZQ71~125B7V3B Service ManualSky-air inverter r-410a b series (484 pages)

- Inverter Daikin D-Series Service ManualSuper multi nx (300 pages)

- Inverter Daikin ERX125A7W1B Installation ManualInverter condensing unit (26 pages)

Summary of Contents for Daikin VRV

- Page 1 i30-408 Basic Training Manual..

- Page 2 VRV system. We wish that you would use this manual as a guidebook for the service of VRV system or as a reference book for education of service personnel, which leads to the development of skills in whole service group of Daikin.

Page 3: Table Of Contents

Si30-408 General Contents General Contents General Contents General Contents A. Introduction........1 B. Basic Information.......21 C. Field Settings from Remote Controller....41 D. Troubleshooting ........ 67 E. Cases for Examination ......109 F. Service Checker Type3 Application Edition ...127 G.- Page 4 Si30-408 General Contents..

- Page 5 A. Introduction A. Introduction A. Introduction 1. What is a VRV System?........2 2. List of VRV Unit Models ........3 2.1 List of Outdoor Unit Models.......3 2.2 Nomenclature ..........5 3. System Basic Configuration .......11 3.1 Cooling / Heating Selection -Standard- System ....11 3.2 Heat Recovery (Cooling / Heating Individual Operating) System..14..

Page 6: What Is A Vrv System

What is a VRV System? Si30-408 1. What is a VRV System? VRV System Thirty or more indoor units can be connected to single system. There are 'cooling / heating selection -standard- type' and 'individual operating system of cooling and heating' according to type of the system.Page 7: List Of Vrv Unit Models

2. List of VRV Unit Models List of Outdoor Unit Models Type R22 C to H series R22 K series VRV Standard C series VRV for High outdoor temp (with unloader comp.) Model Type Service manual Model Type Service manual —..- Page 8 VRV Inverter K series Model Type Service manual RSXYP5-10KJY1 Heat-pump Si-90A RSXP5-10KY1 Cooling only Si33-106 VRV Inverter K series (H/R with Scroll Comp.) Model Type Service manual RSEYP8, 10KJY1 Heat- Si-96 Recovery VRV High COP type L series Model Type..

Page 9: Nomenclature

Si30-408 List of VRV Unit Models Nomenclature 2.2.1 Nomenclature (Previous indication) Indoor Unit Power supply symbol V1 : Single phase 220 to 240V, 50Hz VE : Single phase 220 to 240V, 50Hz : 220V, 60Hz VAL : Single phase 220V, 60Hz..- Page 10 List of VRV Unit Models Si30-408 Indoor Unit Power supply symbol V1 : Single phase 220 to 240V, 50Hz Indicates major design category B: New ceiling suspended cassette K: Wall mounted type 40-63 Capacity Indication Conversion to horsepower: 40 : 1.6HP 50 : 2.0HP..

- Page 11 Si30-408 List of VRV Unit Models Connection Unit (Only Necessary for FUYP Indoor Units) Power supply symbol VE : Single phase 220 to 240V, 50Hz : 220V, 60Hz Indicates major design category Capacity Indication Conversion to horsepower: 71 : 3HP..

- Page 12 List of VRV Unit Models Si30-408 Outdoor Unit (Combination Model Name) The unit with anti-corrosion treatment Power supply symbol Y1 : 3 phase 380 to 415V, 50Hz TAL : 3 phase 220V, 60Hz YAL : 3 phase 380V, 60Hz Indicates major design category..

- Page 13 N : Concealed floor standing type D : Slim ceiling mounted duct type U : Ceiling suspended cassette type (Connection unit series) Indicates that this is VRV system indoor unit. (V2286) BS Unit (Only Necessary for Heat Recovery System) V1 : Single phase 220 to 240V, 50Hz..

- Page 14 List of VRV Unit Models Si30-408 Outdoor Unit B : The unit is for European Standards E : Unit with anti corrosion treatment Power supply symbol Y1 : 3 phase 380 to 415V, 50Hz YL : 3 phase 380V 60Hz..

Page 15: System Basic Configuration

Si30-408 System Basic Configuration 3. System Basic Configuration Cooling / Heating Selection -Standard- System 3.1.1 Type A R(S)XY(P) ~ Outdoor unit • Controls operation mode by using four way valve R22 / R407C • Changing of outdoor heat exchanger to condenser or evaporator Two pieces of piping for liquid and gas Cooling Mode..- Page 16 System Basic Configuration Si30-408 3.1.2 Type B BL 2 ~ 3K (A) : Functional unit RXY ~ K (A) : Inverter unit RNY ~ K (A) : STD unit Functional unit STD unit Inverter unit Enter to functional unit Among outdoor units: three pieces of piping for liquid, from each outdoor unit.

- Page 17 • Changing of outdoor heat exchanger to condenser or evaporator Three pieces of piping for liquid, gas, and oil equalizer Oil equalizer is installed only when outdoor VRV system is connected. Cooling Mode Cooling Mode Normal motorized valve (SH) control..

Page 18: Heat Recovery (cooling / Heating Individual Operating) System

System Basic Configuration Si30-408 Heat Recovery (Cooling / Heating Individual Operating) System R(S)EYP(Q) ~ Outdoor unit • Control operation mode by using plural four way valves • Outdoor heat exchanger is divided and changed to condenser / evaporator based on the load R22 / R407C / R410A BS unit..Page 19: Super Wiring System

Si30-408 Super Wiring System 4. Super Wiring System Points of Super Wiring System Power supply 3-phase, 220 V Outdoor unit Outdoor unit or 380 ~ 415 V (Master unit) (Slave unit) A B C Point Cooling / heating selection All control wires shall be of remote controller Power supply no polarity and two core type.Page 20: Wiring Length

Super Wiring System Si30-408 Wiring Length In super wiring system, limit the wire length within the following number except the wiring of remote controller, due to standardization of wiring for connection between outdoor and indoor unit and centralized transmission lines. The farthest length: 1000m or less, the total wiring length: 2000m or less (When using sheathed wire, the total wiring length can be 1500m or less)Page 21: Refnet Piping

Si30-408 REFNET Piping 5. REFNET Piping Allowable Length of Refrigerant Piping 5.1.1 For RSXY(P) ~ KA(L) Outdoor unit (Slave unit) Outdoor unit (Master unit) #1 refrigerant branch kit Indoor units Indoor units REFNET header Indoor units Allowable Length of Refrigerant Piping (Actual length) Outdoor unit (master) to #1 branch kit to Indoor unit [c] Outdoor unit to Indoor unit (b + c)- Page 22 REFNET Piping Si30-408 5.1.2 For RX(Y)(Q) ~ M Outdoor unit 2 Outdoor unit 1 Outdoor branch kit #1 refrigerant branch kit Indoor units Indoor units REFNET header Indoor units Allowable Length of Refrigerant Piping (Actual Length) Outdoor branch to Outdoor #1 branch kit to idoor unit [c] Outdoor branch to Indoor unit [b + c] unit [a]..

Page 23: For Refrigerant Piping

Si30-408 REFNET Piping Refrigerant Piping Guideline for Tightening Flare Nut (When No Torque Wrench is Available.) Piping size Tightening angle (guideline) Recommended arm length of tool φ6.4 60º ~ 90º Approximately 150mm φ9.5 60º ~ 90º Approximately 200mm φ12.7 30º ~ 60º Approximately 250mm φ15.9 30º..- Page 24 REFNET Piping Si30-408 Introduction..

Page 25: B. Basic Information

B. Basic Information 1. Explanations on P-H Diagram (Refrigerant Characteristics Table).22 2. Concept of Basic Refrigeration Cycle ......23 3. Points of Refrigerant Control of VRV System ....24 3.1 Cooling Operation .........24 3.2 Heating Operation .........25 3.3 Compressor Capacity Control .......26 3.4 Control of Electronic Expansion Valve ......27..Page 26: Explanations On P-h Diagram (refrigerant Characteristics Table)

Explanations on P-H Diagram (Refrigerant Characteristics Table) Si30-408 1. Explanations on P-H Diagram (Refrigerant Characteristics Table) P-H diagram shows characteristics of various refrigerants with pressure on vertical axis and enthalpy on horizontal axis. Isothermal line Subcooled area (Subcooled liquid) Saturated area (Saturated vapor) Superheated area (Superheated vapor)Page 27: Concept Of Basic Refrigeration Cycle

Si30-408 Concept of Basic Refrigeration Cycle 2. Concept of Basic Refrigeration Cycle The refrigeration cycle is composed of repetition of the following process. → → → 'Compression Condensation Expansion Evaporation' The refrigerating machine conducts above cycle with compressor, condenser, expansion valve and evaporator.Page 28: Points Of Refrigerant Control Of Vrv System

Points of Refrigerant Control of VRV System Si30-408 3. Points of Refrigerant Control of VRV System Cooling Operation Subject to change of the number of operation (thermostat-on) units, capacity, air flow rate, suction temperature, humidity change of indoor units Load on total system changes.Page 29: Heating Operation

Si30-408 Points of Refrigerant Control of VRV System Heating Operation Subject to change of the number of operation (thermostat-on) units, capacity, air flow rate, suction temperature, of indoor units Load on total system changes. Loads on every indoor unit are different.Page 30: Compressor Capacity Control

(KJ . kg In the compressor capacity controller of VRV system, the pressure detected (Pe or Pc) by pressure sensor installed in outdoor unit is converted into equivalent saturation temperature, and the evaporation temperature (Te) while cooling or the condensation temperature (Tc) while heating are so controlled with PI control as to put them close to the target value in order to maintain stable capacity in spite of incessantly varying load.Page 31: Control Of Electronic Expansion Valve

Si30-408 Points of Refrigerant Control of VRV System Control of Electronic Expansion Valve Electronic In Cooling Operation In cooling operation, outdoor electronic expansion valve should basically be fully open. Expansion Valve Note: In some models of type L or newer, the valve can be fully closed with a bridge circuit.Page 32: Control Of Indoor Unit

Control of Indoor Unit Si30-408 4. Control of Indoor Unit Thermostat-control 4.1.1 Operation Range of Remote Controller Thermostat Room temperature is controlled by remote controller thermostat side and suction thermostat (body-thermostat) on indoor unit side. (However, when remote controller thermostat is set to 'Not used ' with field setting, the unit can be controlled only by body-thermostat.) Preset temperature (TS)- Page 33 Control of Indoor Unit 4.1.2 Thermostat-control in Normal Operation As to VRV system, remote controller thermostat is set to use when shipped from factory. Normally thermostat differential is set to setting temperature –1°C at cooling, while set to setting temperature +1°C in heating when shipped from factory.

Page 34: Drain Pump Control

Control of Indoor Unit Si30-408 Drain Pump Control 4.2.1 Drain Pump Control (1) When the float switch is actuated during the cooling thermostat ON. Thermostat (Operation) Malfunction stop with 'A3' on remote controller Float switch Drain pump 5 min. 5 min. *1 Residual operation 5 sec.Page 35: Freeze-up Prevention Control

Si30-408 Control of Indoor Unit Freeze-up Prevention Control Freeze-up prevention by off-cycle (The control be carried out with individual indoor unit.) When the temperature detected by liquid pipe temperature thermistor (Th2) of the indoor heat exchanger lowers, and the following ON condition is fulfilled, the unit enters freeze-up prevention operation (forcedly thermostat off).Page 36: Heater Control

Control of Indoor Unit Si30-408 Heater Control 4.4.1 Heater Control of VRV System Optional heater (wiring modification adapter is required) is made on/off under the conditions below. On Condition (All Heating mode & thermostat-on Not under hot-starting Conditions Not under preparation of oil-return or defrosting..Page 37: Thermostat Control In Cooling / Heating Automatic Operation

Si30-408 Control of Indoor Unit Thermostat Control in Cooling / Heating Automatic Operation In cooling / heating automatic operation, the unit is controlled as shown below based on set 'differential value'. Factory setting of differential valve is 5°C. As to charging method of setting value, refer to page 43 and page 44.- Page 38 Control of Indoor Unit Si30-408 Cooling/Heating Differential: at Automatic heating Automatic cooling 22˚C 25˚C 3°C T=3˚C Cooling thermostat ON Cooling thermostat OFF Display selection Cooling→Heating Display selection Heating→Cooling Heating thermostat OFF Heating thermostat ON 3˚C T/2+2˚C(3.5˚C) Cooling/Heating Differential: at 0°C Automatic heating / cooling 25˚C Cooling thermostat ON..

Page 39: Other Functional Operations

Si30-408 Other Functional Operations 5. Other Functional Operations Explanations on Main Functional Control 5.1.1 Cooling Operation Constant evaporation temperature (Te) control Compressor capacity control (Basic target value: R22 = 5.5°C, R407C = 7.5°C, R410A = 6°C *Compensation is applied) Constant superheated degree (SH = Tg – Tl) control Indoor electronic expansion valve (Basically compensation of 5°C is required.Page 40: Explanations On Electric And Functional Components

Other Functional Operations Si30-408 Explanations on Electric and Functional Components 5.2.1 For RSXY8, 10K and RSXYP8, 10KJ Schematic Diagram of Refrigerant Gas pipe Liquid pipe Gas pipe SENPH Th3-1 Th3-2 SENPL Liquid pipe Comp Comp Accumulator Gas pipe Gas pipe Liquid pipe Liquid pipe Basic Information..- Page 41 Si30-408 Other Functional Operations Explanation on Component Function (Electric Parts name Symbol Function symbol) In heating operation standby due to outdoor Outdoor thermistor R1T (Th1) temperature (forcedly thermostat-off at 27°C or higher), influence to defrost condition. In heating operation, used for detection of Heat exchanger thermistor R2T (Th2) defrosting..

- Page 42 Other Functional Operations Si30-408 5.2.2 For RXY(Q)14, 16M Schematic Diagram of Refrigerant Heat exchanger Heat exchanger Heat exchanger Electronic expansion valve Electronic expansion valve Electronic expansion valve Filter Filter Filter Filter Filter Filter Indoor unit Indoor unit Indoor unit Gas pipe Liquid pipe Solenoid valve Receiver..

- Page 43 Si30-408 Other Functional Operations Functional Parts (Electrical Part name Symbol Function symbol) Used to detect outdoor temperature, thus Outdoor thermistor (R1T) compensating discharge pipe temperature and others. Used to detect suction pipe temperature, thus Suction pipe thermistor (R2T) conducting constant control of the suction superheated degree in heating operation.

- Page 44 Other Functional Operations Si30-408 (Electrical Part name Symbol Function symbol) Solenoid valve (Non- On the outdoor unit multi system, used to prevent the operating unit gas SVSG (Y5S) refrigerant from accumulating in outdoor units in stop discharging) mode. Solenoid valve (Non- On the outdoor unit multi system, used to prevent the operating unit liquid pipe SVSL..

Page 45: C. Field Settings From Remote Controller

Si30-408 C. Field Settings from C. Field Settings from C. Field Settings from C. Field Settings from Remote Controller Remote Controller Remote Controller Remote Controller 1. Field Settings from Remote Controller .....42 1.1 Field Setting Mode .........43 1.2 Service Mode .........49 1.3 Check Mode ..........54 1.4 Test Operation Mode........55 2.Page 46: Field Settings From Remote Controller

Field Settings from Remote Controller Si30-408 Field Settings from Remote Controller The following modes can be selected by using the button on the remote CHECK/TEST controller. B-1. Display of Service Data (Mode No. 40/41) B-2. Service Setting (Mode No. 43/44) Service Mode Press and hold the CHECK/TEST button Press and hold the CHECK/TEST button..Page 47: Field Setting Mode

Si30-408 Field Settings from Remote Controller Field Setting Mode 1.1.1 Settings of Individual Functions for Indoor Unit Individual functions of indoor unit can be changed from the remote controller. At the time of installation or after service inspection/repair, make field settings in accordance with the following descriptions.- Page 48 Field Settings from Remote Controller Si30-408 List of Setting Item : Factory setting Mode Setting Setting Position No. Note 2) Switch Setting Contents Note 1) Approx. Approx. Super long life 10,000 5000 Filter contamination-Heavy/ filter hours hours Light (Setting of time intervals to Approx.

- Page 49 Si30-408 Field Settings from Remote Controller 1.1.2 Settings of Group No. for Centralized Control System In order to control with central controller or ON/OFF controller, settings of group No. to each group using remote controller are necessary. (Connect remote controller to indoor unit, which does not need remote controller, then remove the remote controller after setting.) Procedure Turn on the power supply.

- Page 50 Field Settings from Remote Controller Si30-408 Examples of Settings of Group No. Indoor unit Centralized remote controller Group control using remote controller ON/OFF controller (automatic address) Group No. 1-00 1-01 1-02 for centralized control No remote Group control using remote controller controller (automatic address) 1-03..

- Page 51 Si30-408 Field Settings from Remote Controller Examples of Address Settings Group No. for centralized control 1-00 1-01 1-03 AIR CONDITIONER Mode No. For remote control and connecting each indoor Field Set Mode 1-00 units to DIII net. SETTING Group No. TEST Field Settings from Remote Controller..

- Page 52 Field Settings from Remote Controller Si30-408 1.1.3 Settings of AirNet Address For the setting of AirNet address of indoor unit, select mode No. using remote control and follow the procedure below. (Make settings by changing unit No. with no remote control equipped.) The settings of AirNet address make it easy to check indoor unit by using service checker.

Page 53: Service Mode

Si30-408 Field Settings from Remote Controller Service Mode The operation of button of remote controller enables 'service data' gain and 'service settings' with service mode. How to Enter the Service Mode Normal Field setting Service mode operation mode mode button for a period of four button for period of four seconds or more.- Page 54 Field Settings from Remote Controller Si30-408 Example of display on remote Mode No. Function Contents and setting methods controller Display of malfunction Displays malfunction history. Unit code history The history No. can be changed with the Malfunction code button. 2-U4 History No: 1-9 Malfunction code 1: Latest..

- Page 55 Si30-408 Field Settings from Remote Controller 1.2.2 Service Settings Select mode No. Select a desired mode No. by using button. (While in wireless remote controller, setting of '43' forcedly fan ON is only available.) Select unit No. (For group control only) Select indoor unit No.

- Page 56 Field Settings from Remote Controller Si30-408 Mode No. Function Contents and setting method Example of display on remote controller Forcedly fan ON Forcedly fan ON Unit By selecting the unit No. with the button, the fan of each indoor unit will be forcedly turned on (forcedly ON) individually.

- Page 57 Si30-408 Field Settings from Remote Controller Method to Specify the Indoor Unit No. In indoor units where group control is made, mode No. 43 (turn on the forcedly fan) is used to specify the location of installation of the indoor unit with a certain No. (When the malfunction occurs within remote control group, above method can also be utilized to specify the indoor unit which has the trouble.) Procedure..

Page 58: Check Mode

Example of indoor unit model code Display Display Type Model *1: When the operation by RSXY(P) A A 1 VRV System Inverter K Series buttons is not performed A A 3 R407C VRV PLUS Series RXY(P) for a period of 10 seconds, A 9 2..Page 59: Test Operation Mode

Si30-408 Field Settings from Remote Controller Test Operation Mode Putting the system into test operation mode is available by operating the button of remote controller. 1.4.1 Setting of Test Operation Mode Test operation mode setting is available by operating as follows. Normal Test operation operation..Page 60: Field Setting On Outdoor Unit

Field Setting on Outdoor Unit Si30-408 2. Field Setting on Outdoor Unit Using pushbutton switches on the PC board enables a variety of settings. However, setting items and setting No. etc. are different according to the model. The following explanation was made based on the representative models of RX(Y)(Q) ~ M. For further details, refer to each service manual of applicable model of the target machine.Page 61: Explanation Of Basic Mode

Si30-408 Field Setting on Outdoor Unit Explanation of Basic Mode 2.1.1 Setting Mode 1 Normally, the system is set to 'Setting Mode 1'. In other condition, press the MODE button(BS1) once to put the Example of LED display Setting (Display) items system into 'Setting mode 1'.- Page 62 Field Setting on Outdoor Unit Si30-408 2.1.2 Setting Mode 2 Setting item Set Content Press and hold the MODE button In defect of the INV compressor, operation is made only using the (BS1) for a period of five seconds or STD compressor.

- Page 63 Si30-408 Field Setting on Outdoor Unit LED Display Under Cooling/Heating prepa- Setting condition display selection Used Example Page ration, Dema Malfun Indivi- Batch Batch noise dual master slave ction *Factory setting For emergency 8777778 measures by inverter in Normal operation 8777787 individual installation Emergency operation..

- Page 64 8777787 8777778 8777787 Master unit operation: Inhibited For emergency 8777778 measures of the 8777787 outdoor-multi system Slave unit 1 operation: installation Inhibited 8777778 (For the series of VRV II) 8777787 Slave unit 2 operation: Inhibited Field Settings from Remote Controller..

- Page 65 Si30-408 Field Setting on Outdoor Unit 2.1.3 Monitor Mode LED display Data Pressing the MODE button (BS1) Setting items display H1P H2P H3P H4P H5P H6P H7P while in 'Setting mode 1' will enter 9 7 7 7 7 7 7 Refer to 'Monitor mode'.

- Page 66 Field Setting on Outdoor Unit Si30-408 While pressing the button, press the RETURN button when No. 1 to No. 15 LED meets the target, thus making it possible to check respective data. Data expresses addresses or the number of units in binary numbers and 9 797997 has two expression methods.

Page 67: Use Of Each Setting Mode

Si30-408 Field Setting on Outdoor Unit Use of Each Setting Mode 2.2.1 Setting of Operation of Refrigerant Additional Charge When all refrigerants cannot be charged while the outdoor unit operation stops, operate the outdoor unit, then charge refrigerants from the service port of liquid pipe stop valve. Use pushbutton switch on the printed circuit board in outdoor unit to start the refrigerant additional charge operation.- Page 68 Field Setting on Outdoor Unit Si30-408 4. Press the RETURN button (BS3) if the refrigerant is charged to the specified capacity. The operation stops. [The operation stops automatically in maximum approximately 30 minutes. If the additional refrigerant charge is not completed within 30 minutes, set the (A) additional refrigerant charge operation again and start to operate.

- Page 69 Si30-408 Field Setting on Outdoor Unit 2.2.2 Setting of Refrigerant Recovery Mode When the refrigerant is recovered in the field, open the expansion valves in indoor and outdoor units fully. Prohibit the operation of both indoor and outdoor units. Operation 1.

- Page 70 Field Setting on Outdoor Unit Si30-408 2.2.4 Working in the Check Operation Provide the test operation mode and study the following items in order to prevent the malfunction in the field installation: the check for erroneous wiring, the check the stop valve, judging the piping length, judging the refrigerant over-charging, the check for missing thermistor (or reverse connection) in discharging pipe and the minimum opening degree at start of the motorized valve.

Page 71: D. Troubleshooting

Si30-408 D. Troubleshooting D. Troubleshooting D. Troubleshooting D. Troubleshooting 1. For Troubleshooting ........68 2. Check Items before Troubleshooting ......69 2.1 Check Items on Operation Condition (Essential Items as a Minimum) .69 2.2 Check for Malfunction in Cooling Operation......70 2.3 Check for Malfunction in Heating Operation......71 3.Page 72: For Troubleshooting

For Troubleshooting Si30-408 1. For Troubleshooting Every service engineer shall have consciousness, confidence, responsibility, and pride as a service person of manufacturer. According to action patterns shown below, take prompt and on-target measures against defects or failures pointed out by customers. 1.Page 73: Check Items Before Troubleshooting

Si30-408 Check Items before Troubleshooting 2. Check Items before Troubleshooting Check Items on Operation Condition (Essential Items as a Minimum) Check Items for Model name of outdoor unit Outdoor temperature / Suction temperature of the outdoor unit Outdoor Unit High pressure Low pressure Liquid pressure (Measurement is required) Compressor discharge pipe temperature..Page 74: Check For Malfunction In Cooling Operation

Check Items before Troubleshooting Si30-408 Check for Malfunction in Cooling Operation When cooling malfunctions, check on the following factors to specify the state of malfunction (peculiar on site). (In order to avoid an insufficient investigation at the initial check) Year round cooling Outdoor unit short circuit Outdoor temperature High..Page 75: Check For Malfunction In Heating Operation

Si30-408 Check Items before Troubleshooting Check for Malfunction in Heating Operation When heating malfunctions, check on the following factors to specify the state of malfunction (peculiar on site). (In order to avoid an insufficient investigation at the initial check) Cold area, Snowfall area Hot area, urban area Outdoor temperature High..Page 76: Method Of Troubleshooting

3. Method of Troubleshooting Excessive / Insufficient Charging of Refrigerant For VRV system, troubleshooting can be executed only with the operating conditions of air conditioner relating to pressure control and electronic expansion valve control, and the methods of judgment are shown below.- Page 77 Si30-408 Method of Troubleshooting 3.1.1 Change of High / Low Pressure and Frequency with Excessive / Insufficient Refrigerant Gas Charge (Presentation with Image) [For operation with all units connected (100 %)] 1. Excessively Charged Refrigerant Gas Cooling No status change within the range that the receiver can absorb the refrigerant. High pressure stepping down control Frequency becomes to High pressure rises..

Page 78: Troubleshooting

Method of Troubleshooting Si30-408 2. Insufficient Refrigerant Gas Cooling Opening degree of indoor electronic expansion valve increases. Fan control will be executed for maintaining high pressure with low outdoor temperature cooling control Any one of motorized valve is fully open. = Actually, hunting will be generated.Page 79: Abnormal Judgment For Various Sensors

Si30-408 Method of Troubleshooting Abnormal Judgment for Various Sensors When pressure sensor, thermistor or current sensor detects an abnormal value (upper limit value or more, or lower limit value or less), the unit will be halted with display of 'Abnormal cord'.- Page 80 Method of Troubleshooting Si30-408 3.2.1 Thermistor 1. Symptoms with Thermistor Resistance Deviation In Cooling with Superheat • Indoor unit liquid pipe thermistor · When the resistance deviates to smaller value. · When the resistance deviates to larger value. Degree Control (Lower temperature detected) (Higher temperature detected) Superheat degree (SH) = Tg-Tl..

- Page 81 Si30-408 Method of Troubleshooting In Heating with Subcooled • Indoor unit liquid pipe thermistor · When the resistance deviates to larger value. · When the resistance deviates to smaller value. Degree Control (Higher temperature detected) (Lower temperature detected) Subcooled degree (SC) = Tc-Tl Subcooled degree (SC) = Tc-Tl Tc-Tl decreases.

- Page 82 Method of Troubleshooting Si30-408 2. Construction of Thermistor Name Material Thermistor Metallic oxide Glass Dumet wire Coat agent 1 Silicon resin Coat agent 2 Epoxy resin Filling agent Epoxy resin Protective pipe Phosphor deoxidized copper For Thermistor Malfunction Electrolytic corrosion (transfer of cuprous oxide) generated. Troubleshooting..

- Page 83 Si30-408 Method of Troubleshooting Thermistor Temperature · Resistance Characteristic Unit: kΩ Thermisitor Temperature °C –10 112.0 — — 48.48 –8 100.4 — — 43.92 –6 90.2 88.0 866.8 39.84 –4 81.1 79.1 782.7 36.19 –2 73.0 71.1 707.6 32.93 65.8 64.1 640.4 30.00..

- Page 84 Method of Troubleshooting Si30-408 3.2.2 Pressure Sensor Voltage Measuring Point When the color of harness is not as mentioned above, find the measuring point by following procedure. 1. Black is GND. 2. Find DC5V line. 3. The remained wire is the sensing section. (For the same pressure, higher output voltage can be detected with low-pressure sensor, while lower output voltage detected with high pressure sensor.) Troubleshooting..

- Page 85 Si30-408 Method of Troubleshooting Voltage Characteristic of Pressure Sensor (R22, R407C) × High pressure P = (V - 0.5) 0.98 × Low pressure P = (V - 0.5) 0.98 / 3 : Detection pressure [High pressure side] MPa : Detection pressure [Low pressure side] MPa : Output voltage [High pressure side] V : Output voltage [Low pressure side] V Detection pressure..

- Page 86 Method of Troubleshooting Si30-408 Voltage Characteristic of Pressure Sensor (R410A) − = 1.38V 0.69 − = 0.57V 0.28 : Detection pressure [High pressure side] MPa : Detection pressure [Low pressure side] MPa : Output voltage [High pressure side] V : Output voltage [Low pressure side] V Detection pressure High pressure (kg/cm..

Page 87: Structure And Operation Of Electronic Expansion Valve

Structure and Operation of Electronic Expansion Valve For VRV system, EBM type linear control valve is employed to use as an electronic expansion valve for superheated degree control or subcooled degree control. In the valve, single-phase excitation drive type pulse motor is employed. On receiving 2000 pls signal, goes to full open.- Page 88 Method of Troubleshooting Si30-408 3.3.1 Malfunction Example of Electronic Expansion Valve Gas Leakage Malfunction (Full Open) Gas leakage Gears run idle due to wear of gear teeth. Full refrigerant gas in driving section Crack is found in bellows. Moisture entered into the bellows due to the following causes, and froze resulting break of the bellows.

Page 89: Structure And Movements Of Four-way Valve

While in cooling and defrosting in heating, the valve feeds to outdoor heat exchanger. For VRV system standard unit, one four-way valve is installed, however, for some units of other series, plural valves may be installed.- Page 90 Method of Troubleshooting Si30-408 Operation in Heating Coil: energize Internal plunger moves From discharge of compressor Internal piston moves according to pressure difference between high pressure and low pressure. From outdoor unit To indoor heat exchanger heat exchanger To suction of compressor Troubleshooting..

Page 91: Structure And Operation Of Solenoid Valve

Si30-408 Method of Troubleshooting Structure and Operation of Solenoid Valve Guide tube Solenoid valve coil Spring Plunger Valve seat Refrigerant pipe Liquid Injection In order to prevent overheating operation of compressor, refrigerant is injected to compressor suction port from liquid line reducing pressure through capillary tube. The operation is as follows;..Page 92: Structure And Operation Of Two-way Solenoid Valve

Method of Troubleshooting Si30-408 Structure and Operation of Two-way Solenoid Valve In heating operation, when each standard speed outdoor unit does not operate, the two-way solenoid valve stops each gas pipe. This valve is external equalizing type, i.e. pressure difference to move the spool can be made outside of valve.Page 93: Check On Outdoor Fan Motor

Si30-408 Method of Troubleshooting Check on Outdoor Fan Motor Check 1 Check 3 Check on connector of fan motor Check on pulse input of fan inverter PC board (power supply cable) position signal (1) Turn OFF the power supply. (1)Disconnect the connector X2A under the conditions of Check on resistance balance and short-circuiting between power supply OFF and operation OFF.Page 94: Diagnosis On Malfunction Code Of Inverter System

Method of Troubleshooting Si30-408 Diagnosis on Malfunction Code of Inverter System 3.8.1 Understanding of Malfunction Code In case of 3 phase, 200~220V class model (Instantaneous / Overcurrent) AC, DC When DC exceeds 70 A even instantaneously. (Instantaneous / Overcurrent) AC, DC Compressor rocked.- Page 95 30 minutes. Fin thermistor (H / K) For fin thermal during compressor halts Fin thermal (G) Note; (G): VRV-G type, (H): VRV-H type, (K): VRV-K type CT: Detected by direct current converter · CT: Detected by alternative current converter ·..

- Page 96 Method of Troubleshooting Si30-408 3.8.3 How to Use Monitor on Inverter PC Board The latest contents of malfunction stop can be obtained by LED display on inverter PC board. Each malfunction stop of inverter has retry function. Within the specified frequency of retry, the unit merely goes into 5 minutes standby mode, and malfunction cannot be determined.

Page 97: Diagnosis On Transmission System Malfunction

Si30-408 Method of Troubleshooting Diagnosis on Transmission System Malfunction 3.9.1 Understand Entire System (Make a Simple Illustration of the System.) [An example of illustration] PAC-1 PAC-4 Centralized controller ON / OFF controller PAC-2 PAC-5 U4 and U9 generated Schedule timer PAC-3 Installation of DIII-NET expander adaptor In the above figure, each line stands for;..- Page 98 Method of Troubleshooting Si30-408 3.9.2 Cautions in Transmitting Waveform Measurement Make sure the probe is securely connected to respective terminals (F1 and F2) Playing on either of the terminals may deform the waveform, thus resulting in incorrect diagnosis. In order to acquire proper diagnosis, be sure to connect a temporary distributing cable to the probe and fix it to the F1 and F2 with screws.

- Page 99 Si30-408 Method of Troubleshooting 3.9.4 Verification of D-III NET Transmission Waveform Short pulse with 1V or less or overshoot of waveform at start-up is not problem. When the waveform as shown below appears in measuring of transmission waveform, transmission malfunction may probably be caused. (Ringing) (Round pulse) (Noise)

Page 100: Malfunction Tree Analysis (fta)

For analyzing a symptom, put the causes relating to the phenomenon in a dendritic figure. For project with VRV system, general contractors and subcontractors generally enter in the supply route. As a recent trend, they often request an explanation with FTA method. (i.e., only a reasonable explanation can be accepted.)Page 101: Actuation Of Freeze-up Prevention Control Of Indoor Unit

Si30-408 Malfunction Tree Analysis (FTA) Actuation of Freeze-up Prevention Control of Indoor Unit Faulty design (Soft miss) Faulty control PC board Faulty compressor capacity control Faulty low False detection pressure sensor of pressure Faulty driving part Faulty expansion Faulty valve Faulty actuation valve body..Page 102: Actuation Of Hps In Heating Operation

Malfunction Tree Analysis (FTA) Si30-408 Actuation of HPS in Heating Operation Faulty outdoor fan operation Faulty outdoor electronic expansion valve Faulty high- operation pressure control Faulty design Faulty control PC board False detection of Faulty high- pressure pressure sensor Outside of scope of using outdoor air temp.Page 103: Abnormal Discharge Pipe Temperature In Cooling Operation

Si30-408 Malfunction Tree Analysis (FTA) Abnormal Discharge Pipe Temperature in Cooling Operation Faulty design Faulty solenoid valve Faulty discharge pipe control Clogged path Faulty liquid injection circuit operation Faulty coil Faulty control PC board Faulty compressor Discharge Faulty Faulty hot gas bypass valve operation temperature compressor rises..Page 104: Water Leakage From Indoor Unit

Malfunction Tree Analysis (FTA) Si30-408 Water Leakage from Indoor Unit Dirty air filter, heat exchanger Air flow shortage Faulty fan motor Malfunction of refrigerant system Waterdrop fall down Refrigerant deflection from fin Refrigerant shortage Adhesion of waterdrop caused by heat exchange water repellent (misting) Heat exchanger water repellent..Page 105: Defective Lubrication Of Compressor

Si30-408 Malfunction Tree Analysis (FTA) Defective Lubrication of Compressor Clogged oil return capillary Clogged oil return Clogged oil path separator Clogged refrigerant filter Clogged feed oil path (Feed oil pump failure) Gas leakage Shortage of gas Refrigerant Oil return Abnormal piping charging low volume low length..Page 106: List Of Malfunction Code

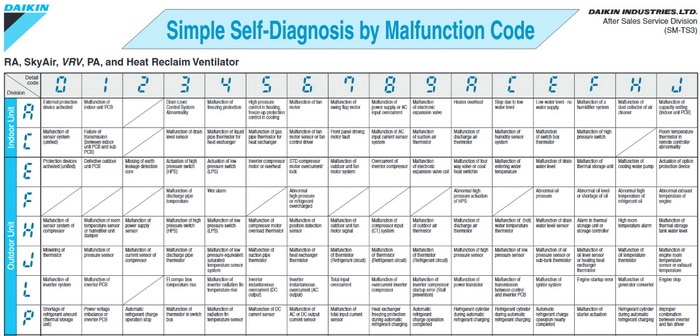

List of Malfunction Code Si30-408 5. List of Malfunction Code Content code Section code Malfunction PC board Malfunction Fan motor Malfunction of external ass'y of drain level locked of swing flap protection Faulty control motor device EEPROM system setting Indoor Malfunction Malfunction of thermistor..- Page 107 Si30-408 List of Malfunction Code Malfunction of Malfunction of Abnormal drain Malfunction of dust collecting capacity setting driving part of element electronic expansion valve Malfunction of Malfunction of Malfunction of thermistor for thermistor for remote suction air discharge air controller (Faulty contact (Faulty contact sensor..

- Page 108 List of Malfunction Code Si30-408 Malfunction Code Display by Outdoor Unit PC Board Malfunction Contents of malfunction code Monitor mode Abnormal discharge pressure HPS actuation Abnormal suction pressure Abnormal Pe To enter the monitor mode, press the Compressor lock Detection of INV compressor lock MODE button (BS1) when in 'Setting OC actuation Detection of STD1 compressor lock..

- Page 109 Si30-408 List of Malfunction Code Malfunc Check of malfunction 1 Check of malfunction 2 Check of malfunction 3 -tion code LED1 LED2 LED3 LED4 LED5 LED6 LED7 LED1 LED2 LED3 LED4 LED5 LED6 LED7 LED1 LED2 LED3 LED4 LED5 LED6 LED7 Troubleshooting..

- Page 110 List of Malfunction Code Si30-408 Malfunction Contents of malfunction code Open phase / Power supply Imbalance of inverter power supply imbalance voltage Malfunction of temperature sensor Malfunction of thermistor for inverter inside switch box Malfunction of sensor for inverter Malfunction of thermistor for inverter radiation fin temperature Faulty combination of inverter and Incorrect combination of inverter and..

- Page 111 Si30-408 List of Malfunction Code Malfunc Check of malfunction 1 Check of malfunction 2 Check of malfunction 3 -tion LED1 LED2 LED3 LED4 LED5 LED6 LED7 LED1 LED2 LED3 LED4 LED5 LED6 LED7 LED1 LED2 LED3 LED4 LED5 LED6 LED7 code 4:ON Malfunction code 1st..

Page 112: Operating Condition Check Sheet

Operating Condition Check Sheet Si30-408 6. Operating Condition Check Sheet Content of malfunction: Service shop: Person in charge: Model name Serial No. System name, Installation site Outdoor unit Indoor unit No.1 No.2 No. of unit connected unit(s) No.3 No.4 Capacity No.5 No.6 No.7..Page 113: E. Cases For Examination

Si30-408 E. Cases for Examination E. Cases for Examination E. Cases for Examination E. Cases for Examination 1. VRV in General ..........110 2. Indoor Unit Related Examples ......121 3. Malfunction of Transmission Examples.....123 Cases for Examination..- Page 114 Applicable VRV Plus series (L unit) Models Condition Though an malfunction 'E3 (abnormal high-pressure)' is sometimes displayed on the VRV Plus series (L unit) system, the same condition is not reproduced at the time of inspection (unintentional operation). Cause Electronic expansion valve of the STD outdoor unit 2, which must be opened fully during cooling operation, is malfunctioning.

- Page 115 Point of Setting the horsepower corresponding to the capacity of the model is needed after replacing the control PC board of VRV. Diagnosis For setting methods, refer to the page 199 '4. Field settings for replacement of the spare control PC board'..

- Page 116 LED display for master/slave judgment remained to be turned off the test operation of the multi system of two VRV II units though the unit being connected to the indoor-to-outdoor unit connection wire should be judged as a master unit normally.

- Page 117 RX(Y)(Q) ~ M (VRV II series) Models Condition Demand control with an externally controll adapter attached to the VRV II series outdoor unit is desired. Thermostat does not turn off though C and 3 were short-circuited i.e., demand level 3, after setting.

- Page 118 VRV in General Si30-408 Malfunction Cooling Operation Applicable VRV in general (Type K or later models) Models Condition Different systems are used to air-condition the 1st floor and the 2nd floor. Compared with the 1st floor, 2nd floor is not cooled down well. (Though the system for the 2nd floor operates normally, timing when its thermostat turns OFF is early compared with the one for the 1st floor.)

- Page 119 Si30-408 VRV in General 1.10 Inferior Insulation of the Compressor before Test Operation Applicable VRV in general Models Condition At the time of test operation, compressor was replaced since the insulation was found insufficient in the insulation measurement with the power not supplied.

- Page 120 VRV in General Si30-408 1.12 Inverter Compressor Fails Three Times a Month Applicable VRV in general Models Condition Cause Due to foreign matters clogging between the oil separator and the filter, oil does not return to the compressor. Measure Recovers by replacing the refrigerant filter.

- Page 121 Si30-408 VRV in General 1.14 Malfunction Heating Due to Overcharge of Refrigerant Applicable VRV in general Models Condition Inverter compressor only operates at low frequency. Discharge temperature of the indoor units is 25°C or less and thermistor temperature of the liquid pipe is approx. 30°C when it is monitored through the service mode of the indoor remote controller.

- Page 122 It caused to fully open the electronic expansion valve mounted to the indoor unit and resulted in backflow of liquid. (Indoor units of VRV set to stop operation after completion of the day's work, however, the outside air processing unit set to operate around the clock.) Measure Recovers by replacing the EV drive section of the outside air processing unit.

- Page 123 Drop of temperature in discharge air due to indoor unit's capacity control. (Temperature set by the remote controller was as low as 22°C.) In order to prevent hunting of indoor temperature due to ON/OFF switching of thermostat, VRV uses an electronic expansion valve mounted to the indoor unit to control the flow rate (capacity control) of refrigerant.

- Page 124 VRV in General Si30-408 1.18 Outdoor Unit of the Cooling Only Model Operates with Heating Operation Displayed. Applicable VRV in general Models Condition Outdoor unit started operation when operation is initiated with the heating operation displayed in the local remote controller.

- Page 125 Si30-408 Indoor Unit Related Examples 2. Indoor Unit Related Examples Temperature is not Displayed on the Central Controller. Applicable FXMQ125MF + controller Models Condition Though the FXYMP140MF (outside air processing unit) was built in the control range of the centralized controller, no temperature is displayed on the centralized controller. Temperature is displayed on the remote controller.

- Page 126 Indoor Unit Related Examples Si30-408 Water Leakage from the Ceiling Duct Applicable FXYMJ140KC + Optional humidifier (Japanese Domestic case) Models Condition Indoor unit with ceiling duct +Natural evaporation type humidifier + High-lift drain-up kit Water leakage occurs when the power of (FXYMJ140KC) and (KNMJ30L140) indoor units is shut off.

- Page 127 [Malfunction of Transmission Examples] Display of Malfunction of Transmission due to the Elevator's Power Line Applicable VRV in general Models Condition A malfunction 'UE' is issued at random. It continues to be generated maximum 30 seconds. Transmitted waveforms were checked to be distorted for a period of approx. 10 seconds on site.

- Page 128 Malfunction of Transmission Examples Si30-408 [Malfunction of Transmission Examples] Faulty Condition to Multi-core Wire Applicable VRV in general Models Condition Cause According to the wiring company, two-core lines were to be used as transmission line. However, multi-core lines are used actually. There was also a case where two cores out of four cores were being used for power supply.

- Page 129 Malfunction of Transmission Examples [Malfunction of Transmission Examples] 'Under Centralized Control' is Displayed on the Individual Remote Controller. Applicable VRV in general Models Condition 'Under central control' is displayed on the individual remote controller and operation by the remote controller is disabled.

- Page 130 Malfunction of Transmission Examples Si30-408 [Malfunction of Transmission Examples] A Malfunction 'UE' is Sometimes Issued. Applicable Heat recovery VRV system Models Condition Cause One BS unit in the system was oscillating. Measure Completed by mounting a DIII-NET expander adapter. Point of..

- Page 131 Application Edition Application Edition Application Edition 1. List of Applicable Models of TYPE3 ......128 1.1 VRV Multi Systems (R410A/R407C/R22) .....128 2. What Service Checker Can Do ......130 3. Recording and Playback of Operation Data....137 3.1 Menu Window (Map Mode) .......137 3.2 Periodical Recording Setting Window .....139..

Page 132: List Of Applicable Models Of Type3

*2 VRV Plus (Cooling only, Heat pump) for high outdoor temperature use up to 50degC. Condenser Unit. *3 On VRV II heat recovery series, outdoor unit data is split off into common and individual sections. Consequently, two units of icons are displayed even for a single outdoor unit.- Page 133 *8 Connect any model of VRV Plus series to applicable function units or cooling plus units. *9 If the Service Checker is connected to the PC board, information on indoor units will be integrated into a single indoor unit of data.

Page 134: What Service Checker Can Do

What Service Checker Can Do Si30-408 2. What Service Checker Can Do 1. The Service Checker makes it possible to make the pass/fail judgment on and check the performance of functional parts in the following cases. (Thermistor, pressure sensor, solenoid valve, and four-way valve) You should know temperature (or pressure) detected by the thermistor (or pressure sensor): You should check whether or not there is a difference between the temperatures..- Page 135 Si30-408 What Service Checker Can Do To Conduct If you collect or analyze data on the Service Checker: Analysis First of all, make the pass/fail judgment on functional parts. For accurate data collection, be sure to check the functional parts for any problem. Case example: Even though the thermistor showed a normal value at an ambient temperature, the detection data got out of order with increasing temperature.

- Page 136 What Service Checker Can Do Si30-408 Procedure Select and click an applicable item on the main menu. Procedure Click on the Customer Name (Site Name) registration tab. If the Customer Name registration has been made, click on the “Select customer” and select a Customer Name in the list displayed on the window.

- Page 137 Si30-408 What Service Checker Can Do Procedure Register the Customer ID and Customer Name (Site Name). For the registration, only enter the Customer ID and Customer Name. For any other items, enter them as needed. Service Checker Type3 Application Edition..

- Page 138 What Service Checker Can Do Si30-408 Procedure Register the system. Select menu “For a new customer” or “For a project with Customer Name registered”. Service Checker Type3 Application Edition..

- Page 139 Si30-408 What Service Checker Can Do Procedure Select the method of registering and connecting systems. Enter the “System Name” and then select the “Connecting Method”. For the connecting method, check either “DIII-NET” or “PCB connection”. If you attempt to record data through the use of DIII-NET (F1, F2 connection), the warning above will appear on the window.

- Page 140 What Service Checker Can Do Si30-408 Even tough all settings have been made and the window has been switched, if no data is read and the above error is displayed on the window, the following causes will be supposed. • “F1 and F2” is not well connected, •..

Page 141: Recording And Playback Of Operation Data

Si30-408 Recording and Playback of Operation Data 3. Recording and Playback of Operation Data Menu Window (Map Mode) If the units are properly read, the above window will appear. If the above window appears, select an operation to be conducted on the menu icons. Caution The number of outdoor units varies with the number of sensors.- Page 142 Recording and Playback of Operation Data Si30-408 Selecting recording mode (F5) will display the above window. Click on the “Period. rcd. set” button and make setting of periodical recording. Service Checker Type3 Application Edition..

Page 143: Periodical Recording Setting Window

Si30-408 Recording and Playback of Operation Data Periodical Recording Setting Window Make settings of periodical recording. Selection of system to be recorded — Be conscious only to select a system for which data should be collected. (Otherwise, data memory will run down in a shorter period of time.) Setting of conditions for ending recording —..- Page 144 Recording and Playback of Operation Data Si30-408 Make settings of periodical recording. Setting of recording intervals — Set the recording intervals to 60 seconds unless otherwise specified by Quality Control Dept., or else. Be sure to check the free data space. After the completion of all settings, click on the “Setting completed”..

- Page 145 Si30-408 Recording and Playback of Operation Data Make settings of periodical recording. Click on the “Period. rcd. Start” button. — Periodical recording starts — Check whether or not the recording process is in progress. Check to be sure “In period. recording” is displayed. To end recording Click on the “Period.

Page 146: Centralized Operation (f7)

Recording and Playback of Operation Data Si30-408 Centralized Operation (F7) Make settings of periodical recording. Click on the 'Centralized operation' button on the Menu window. The centralized operation is the same as operation on centralized remote controller. Caution Address settings should be made on the remote controller for indoor units. Display of Operation Data Display operation data.- Page 147 Si30-408 Recording and Playback of Operation Data Display of operation data (Operation data can be displayed even while in recording mode.) Click on the “Detail data input” button on the Menu window. — The above window will be displayed. — Digital data will be displayed at the right on the window.

Page 148: Playback Of Data Recorded

Recording and Playback of Operation Data Si30-408 Playback of Data Recorded Playback of operation data Click on the “Play” button on the Menu window shown above. Highlight data to be played back on the operation data shown in figure above and then click on the “Ope.- Page 149 Si30-408 Recording and Playback of Operation Data Buttons Contents Enlargement (F1) Used to display the graph for a period of time shortened. Reduction (F2) Used to display the graph for a period of time prolonged. Backward (F3) Used to move the graph to the left on the window. Forward (F4) Used to move the graph to the right on the window.

Page 150: Collection And Playback Of Data On Checker

Collection and Playback of Data on Checker Si30-408 4. Collection and Playback of Data on Checker For collection and playback of data on Checker Caution 1. Be sure to check the Nos. of system and indoor unit of the system, on which a malfunction occurs.Page 151: Retrieval Of Raw Data

Si30-408 Collection and Playback of Data on Checker Retrieval of Raw Data Retrieve raw (unprocessed) data. → Use this data to e-mail or else. 1. Boot up the Checker software and then click on the “Data transfer” button. 2. Use the following procedure to transfer the data. 1.- Page 152 Collection and Playback of Data on Checker Si30-408 The following files (of two types) are transferred to the folder. (In the case of a single data transfer) [Customer data file] File name: “Customer ID.dak” [Data file] File name: “Alphanumeric character.das” [Customer data file] [Data file] In order to e-mail data, attach the file (data file) shown above to the e-mail.

Page 153: Retrieval Of Processed Data

Si30-408 Collection and Playback of Data on Checker Retrieval of Processed Data 1. Boot up the Checker software and then click on the 'Play' button. 2. Use the following procedure to carry out CSV conversion of data. 1. Highlight operation data to be retrieved. 2.- Page 154 Collection and Playback of Data on Checker Si30-408 3. Use the following procedure to save converted data. 1. Specify a place to save the data. 2. Enter the data name. 3. Click on the “Save” button. Service Checker Type3 Application Edition..

Page 155: Data Processing

Si30-408 Collection and Playback of Data on Checker Data Processing Process data collected after the CSV conversion. This processing is a method of data analysis on the EXCEL window or in graphical form. 1. Analysis of EXCEL Data Opening data CSV-converted will display the window shown below. On this window, delete “Customer data”..- Page 156 Collection and Playback of Data on Checker Si30-408 Adjust the width of columns. Service Checker Type3 Application Edition..

- Page 157 Si30-408 Collection and Playback of Data on Checker A number of “ON” and “OFF” are mixed on the current setting, thus making the window hard-to-read. Therefore, make settings in accordance with the procedure shown below, in order to facilitate reading. The following window will be displayed.

- Page 158 Collection and Playback of Data on Checker Si30-408 Only “ON”s are displayed, thus facilitating reading the data. It is effective to replace a variety of functional parts and control (e.g. four-way valves, solenoid valves, or drooping control) as well. Service Checker Type3 Application Edition..

- Page 159 Si30-408 Collection and Playback of Data on Checker Pane fixing Service Checker Type3 Application Edition..

- Page 160 Collection and Playback of Data on Checker Si30-408 The title (on the first line) and time (in Column A) of data series is fixed, thus facilitating the Verification of data. Service Checker Type3 Application Edition..

- Page 161 Si30-408 Collection and Playback of Data on Checker Screening (or coloring) data to be noted facilitates the analysis on the data. Service Checker Type3 Application Edition..

- Page 162 Collection and Playback of Data on Checker Si30-408 Method of verification using auto filter In order to carry out data collection for an extended period of one or two weeks to verify the case of intermittent occurrences of malfunctions, the volume of data will become huge, thus taking time to verify the data.

- Page 163 Si30-408 Collection and Playback of Data on Checker Pressing the button corresponding to items to be noted will list and display all elements contained in the column items. ⎡ ⎤ Left figure lists the column ⎢ ⎥ items of “Error codes”. “E0” ⎢..

- Page 164 Collection and Playback of Data on Checker Si30-408 This information shows that “E0” occurred at 16:01 on the 484th line. In this case, cancel the auto filter and then define the causes of the malfunction according to data prior and subsequent to the time when the malfunction occurred. Furthermore, using the auto filter enables the following verification.

- Page 165 Si30-408 Collection and Playback of Data on Checker On the “Page Setup” window, Printing direction → “Landscape” Paper size → Set to “A4 or A3 (if printable)”. Use the 'Margins' tab to adjust the margin so that the global paper will be printed. Service Checker Type3 Application Edition..

- Page 166 Collection and Playback of Data on Checker Si30-408 Service Checker Type3 Application Edition..

- Page 167 Si30-408 Collection and Playback of Data on Checker Exit the “Print preview”, click on the 'File' tab and then highlight the “Page Setup”. On the “Sheet” menu within the “Page Setup” window, click on the “Print titles” and “Rows to repeat at top”..

- Page 168 Collection and Playback of Data on Checker Si30-408 On the “Sheet” menu within the “Page Setup” window, check the “Gridlines” box of the Print section . Checking on the “Print preview” window, the closing lines of cells are displayed. Service Checker Type3 Application Edition..

- Page 169 Si30-408 Collection and Playback of Data on Checker Setting of reduced print Setting figures in the 'Enlarged/Reduced' box to 50% or so (initial setting to 100%) will make it possible to print all items in a sheet of paper. (Adjust the percent values in accordance with the number of data items to be printed.) Print the EXCEL data, and check and verify the data.

- Page 170 Collection and Playback of Data on Checker Si30-408 2. Plotting in Graph There are cases where it is hard to keep track of the overall variations of data on the CSV data. In this case, graphing the data will facilitate the verification of the data. (The following section shows an example of the graphing procedure.) 1.

- Page 171 Si30-408 Collection and Playback of Data on Checker Service Checker Type3 Application Edition..

Page 172: Organizing Graph

Collection and Playback of Data on Checker Si30-408 Organizing Graph Service Checker Type3 Application Edition..- Page 173 Si30-408 Collection and Playback of Data on Checker As shown in the window in previous page, all items contained in the Checker data are graphed. Therefore, for unnecessary items, click on the 'Legend' (shown in window below) or item lines to delete them.

Page 174: Using Secondary Axis

Collection and Playback of Data on Checker Si30-408 Using Secondary Axis If “Opening degree of electronic expansion valve” is selected from the data, due to large amplitude range of 0 to 2000 pulses, the temperature data will be gathered at the bottom of the graph, thus resulting in hard verification of data.- Page 175 Si30-408 Collection and Playback of Data on Checker [Reference 1] [Reference 2] Service Checker Type3 Application Edition..

Page 176: Traverse Of X Axis

Collection and Playback of Data on Checker Si30-408 Traverse of X Axis Since the intersection of X and Y axes is “0” on the current graph , change this intersection to facilitate the reading of the graph. Service Checker Type3 Application Edition..- Page 177 Si30-408 Collection and Playback of Data on Checker [Reference 3] Graphing of ON/OFF data on Checker data Convert “ON” → “120 (Arbitrary)” Service Checker Type3 Application Edition..

- Page 178 Collection and Playback of Data on Checker Si30-408 [Reference 4] Adding data after the graph is plotted. Service Checker Type3 Application Edition..

- Page 179 Si30-408 Collection and Playback of Data on Checker Service Checker Type3 Application Edition..

- Page 180 Collection and Playback of Data on Checker Si30-408 Service Checker Type3 Application Edition..

- Page 181 Si30-408 Collection and Playback of Data on Checker [Reference 5] Plotting of data on indoor and outdoor units in one and same graph Caution The data on indoor units are sampled at 5-minute intervals and, therefore, do not follow the data on outdoor units on an anytime basis.

Page 182: Points Of Analysis

Points of Analysis Si30-408 5. Points of Analysis Method of Use by Symptom In the Case of Faulty Compressor 1. While the compressor is running: Compressor oil temp. > Evaporating temp. (Low pressure saturation temp.) + 10°C Discharge superheated degree (Discharge pipe temp. − Condensing temp. (High pressure saturation temp.- Page 183 Si30-408 Points of Analysis Pay attention to “Condensing temp./Evaporating temp.” rather than to “High pressure/Low pressure”. High and low pressures detected by each pressure sensor are displayed in values, converted into pressure equivalent saturation temperatures, and used as target values for the capacity control.

Page 184: Effective Use Of Checker

Points of Analysis Si30-408 Effective Use of Checker Probe causes of wet operation using the Checker in combination with sensor kits. Most of current malfunctions on compressors result from seizing of or damage to the compressors due to the dilution of lubricant (refrigerant oil) caused while the compressors are in wet operation.Page 185: Example Of Checker Connection

Si30-408 Points of Analysis Example of Checker Connection Service Checker Type3 Application Edition..Page 186: Method Of Mounting Sensor Kit

Points of Analysis Si30-408 Method of Mounting Sensor Kit 1. Determine the position to mount thermistor. 2. Clean the pipe. (Wipe condensate or dirt off the pipe, if any.) Caution Be sure to stop equipment before mounting the thermistor to a low temperature pipe. (If the pipe is condensed or frozen, no accurate measurements are enabled.) 3.Page 187: Place To Save Data

Si30-408 Points of Analysis Place to Save Data The DIII data is used to save transmission data on air conditioners. However, this data cannot be analyzed with the Service Checker. (If Quality Control Department from factory gives an instruction, collect and transmit the data.) Service Checker Type3 Application Edition..- Page 188 Points of Analysis Si30-408 (Case Example) EXIII: Abnormal discharge pipe temperature Unit supplied: RSXYJ140KC (Japanese domestic model) equivalent to RSXY5K. Malfunction conditions: The compressor stops due to the abnormal high temperature of discharge pipe (F3) approximately once a week. Discharge pipe temperature control When the compressor reaches the discharge pipe temp.

- Page 189 Si30-408 Points of Analysis (Case Example) VRV II Heat recovery type: Malfunction of heating Unit supplied: REYQ16M (Heat recovery type) Malfunction conditions: Indoor units produce abnormal sounds sometimes and do not heat up. Referring to Checker data on occurrence of malfunction while in all-unit heating operation (graph shown on the following page) The suction pipe temperature has risen up to approximately 70°C.

- Page 190 Points of Analysis Si30-408 Data on occurrence of malfunction while in all-unit heating operation Graph of indoor unit (1) Indoor unit (1) Service Checker Type3 Application Edition..

- Page 191 Si30-408 Points of Analysis Graph of indoor unit (2) Indoor unit (2) Graph of indoor unit (3) Indoor unit (3) Service Checker Type3 Application Edition..

- Page 192 Points of Analysis Si30-408 Graph of indoor unit (4) Indoor unit (4) Graph of indoor unit (5) Indoor unit (5) Service Checker Type3 Application Edition..

- Page 193 Si30-408 Points of Analysis (Case Example) Ve-up STD RSXYP 5-10L:Malfunction of heating (Indoor units are all in fan operation mode.) Features of data The system is under heating overload (high pressure stepping down) control. The condensing temperature (high pressure) has reached the target value. The operating frequency of INV compressor does not increase.

- Page 194 Points of Analysis Si30-408 Service Checker Type3 Application Edition..

Page 195: G. Appendix

Si30-408 G. Appendix G. Appendix G. Appendix G. Appendix 1. Characteristics of Refrigerant.......192 1.1 R22............192 1.2 R407C ..........193 1.3 R410A ..........195 2. Psychrometric Chart........197 3. How to Calculate Cooling / Heating Capacity ....198 4. Field Settings for the Replacement of the Spare Control PC Board ..199 5.Page 196: Characteristics Of Refrigerant

Characteristics of Refrigerant Si30-408 1. Characteristics of Refrigerant The pressure values in the diagram show absolute pressure. Deduct 0.1MPa to obtain gauge pressure. Appendix..Page 197: R407c

Si30-408 Characteristics of Refrigerant R407C P(MPa) The pressure values in the diagram show absolute pressure. Deduct 0.1MPa to obtain gauge pressure. Appendix..- Page 198 Characteristics of Refrigerant Si30-408 (R407C) Liquid temperature Gas temperature (kg/cm 20.4 15.3 10.2 −40 −20 Temperature (˚C) (R407C) Temperature Temperature Temperature Pressure Pressure Pressure Liquid side Gas side Liquid side Gas side Liquid side Gas side °C °C °C °C °C °C 0.00..

Page 199: R410a

Si30-408 Characteristics of Refrigerant R410A P(MPa) The pressure values in the diagram show absolute pressure. Deduct 0.1MPa to obtain gauge pressure. Appendix..- Page 200 Characteristics of Refrigerant Si30-408 (R410A Thermodynamical Characteristics) DAIREP ver2.0 Specific heat at Specific entropy Vapor pressure Density Specific enthalpy constant pressure (kJ/kgK) (kPa) (kg/m (kJ/kg) Temperature (kJ/kgK) (°C) Liquid Vapor Liquid Vapor Liquid Vapor Liquid Vapor Liquid Vapor –70 36.13 36.11 1410.7 1.582..

Page 201: Psychrometric Chart

Si30-408 Psychrometric Chart Psychrometric Chart Appendix..Page 202: How To Calculate Cooling / Heating Capacity

How to Calculate Cooling / Heating Capacity Si30-408 3. How to Calculate Cooling / Heating Capacity Measure the temperatures of suction air and discharge air of indoor unit. Then, calculate the capacity by using the psychrometric chart. How to calculate the cooling capacity Cooling capacity = (Enthalpy of suction air –..Page 203: Field Settings For The Replacement Of The Spare Control Pc Board

Si30-408 Field Settings for the Replacement of the Spare Control PC Board 4. Field Settings for the Replacement of the Spare Control PC Board Horsepower should be set by using the switch on the PC board when the control PC board is replaced.- Page 204 Field Settings for the Replacement of the Spare Control PC Board Si30-408 2. RSXYP5, 8, 10L In order to replace by the space PC board, change the setting of DIP switch (DS1) on the PC board as shown below. Default condition of DIP switch DS1-7 DS1-8 3.

Page 205: Adaptors For Connection Of Air Conditioners

Si30-408 Adaptors for Connection of Air Conditioners 5. Adaptors for Connection of Air Conditioners Wiring Adaptor for Electrical Appendices <KRP4A51, 52, 53, 54> <Application / Intended use> This adapter enables remote operation control, remote temperature setting, operation display, fetch of malfunction display, and others, but cannot be used in combination with other centralized controllers.- Page 206 Use the relay harnesses (1) and (2) provided to connect wires as shown in figure above. Connect the relay harness (1) to the connector on the indoor unit PC board ass'y (i.e., X18A on VRV). The relay harness (2) has no polarities. Connect wires to terminals P1 and P2 on the connecting wiring terminal block provided in the indoor unit switch box.

- Page 207 Si30-408 Adaptors for Connection of Air Conditioners 2. Setting of CONTROL MODE selector switch (RS1) Use the CONTROL MODE selector switch (RS1) to make selection and setting of control mode through input A or B. To use the system only for display function only in individual display mode Position Function Individual display (with input ignored)

- Page 208 Adaptors for Connection of Air Conditioners Si30-408 To operate the system on two input contacts using instantaneous input for the input A and input B (Use instantaneous input with ON time of 200 msec or more for the input A.) Position Function Contents of input A..

- Page 209 Si30-408 Adaptors for Connection of Air Conditioners 4. Fetch of display signals Normal operation output terminals (W1 and W2) and malfunction output terminals (W3 and W4) are used for no-voltage normal contact output. (Allowable current is 10mA to 3A per contact.) Caution In order to use power supply of 220 ~ 240 VAC, keep the power supply cable away from input wirings.

- Page 210 Adaptors for Connection of Air Conditioners Si30-408 5.1.3 Settings of Remote Control Mode Selector Switch (RS1) Contents of operations in input mode A or B Function Position Input A (Between B1 and Bc) Input B (Between B2 and Bc) Disregard for input —..

- Page 211 Si30-408 Adaptors for Connection of Air Conditioners 5.1.4 Function (Overview) 1. ON / OFF control impossible by remote controller Used to operate or stop the system only on the group remote control adapter side. (Operation / Stop from the remote controller is disabled.) 2.

- Page 212 Cut the spare jumper (J5) connected to wiring adaptor for electrical appendices (2). (If the use conditions shown below are not satisfied, however, the adapter may not normally function.) To indoor unit VRV: X18 Cut this jumper. To terminal blocks (P1 and P2) of..

Page 213: Wiring Adaptor For Electrical Appendices (1) (krp2a61, 62)

Si30-408 Adaptors for Connection of Air Conditioners Wiring Adaptor for Electrical Appendices (KRP2A61, 62) Application / This adapter enables remote operation control, remote temperature setting, operation display, fetch of malfunction display, and others, but cannot be used in combination with other Intended use centralized controllers.- Page 214 Adaptors for Connection of Air Conditioners Si30-408 5.2.2 Wiring 1. For a start, make wire connections between the indoor and outdoor units, between respective power supplied, and between the indoor unit and remote controller, and then check whether nor not the units normally operate. (Particularly, in order to use this adapter in combination with the group control of the remote controller, check to be sure the jumper wiring.) For details, refer to information in the Installation Manual of indoor unit and outdoor unit.

- Page 215 Si30-408 Adaptors for Connection of Air Conditioners For individual display: The wiring procedure is the same as that for the individual control. Do not set the control mode selector switch (RS1) Set the display output to Position 0. Not heeding this will not operate the switch (SS3) to system due to the malfunction of setting.

- Page 216 Adaptors for Connection of Air Conditioners Si30-408 Wiring to External 1. Input for distant control (operation) Depending on whether the INPUT selector switch is set to the “Voltage” or “No-voltage”, Controller connect wires according to the procedure shown below. (e.g. Centralized Control Monitor) For input in 'VOLT'..

- Page 217 Si30-408 Adaptors for Connection of Air Conditioners Caution The input B is used for forcedly OFF. If this input B is turned ON, the system will be put into “Stop + Remote controller inhibited”, thus disregarding the input A. Even if the input A is turned ON with the input B in an OFF state, the content with the input A turned ON will not be provided.

- Page 218 Adaptors for Connection of Air Conditioners Si30-408 3. Input of temperature settings In order to make temperature settings from both distant and remote controller, set this switch to 'Permitted'. (Factory set: Permitted) Permitted: Use this mode to make temperature settings from both distant and remote controllers.

- Page 219 Si30-408 Adaptors for Connection of Air Conditioners The following table shows the output by system. Output Both Ry1 & Only RY1 is turned Ry2 are Only Ry2 is turned ON. System turned OFF. Individual control The system stops due to malfunction or or individual Stop Normal operation..

Page 220: External Control Adaptor Of Outdoor Unit

Adaptors for Connection of Air Conditioners Si30-408 External Control Adaptor of Outdoor Unit <DTA104A53, 61, 62> Application / This adapter is built in the indoor unit or BS unit connected through DIII-NET to select the operation mode (Cooling / Heating / Fan operation) in a batch on multiple outdoor units. Intended Use Overview of 1.- Page 221 Si30-408 Adaptors for Connection of Air Conditioners 5.3.1 Part Names and Functions Power supply connector (D1,D2) To adaptor power supply connector on Don't move it. indoor unit or BS unit Function switch (SS1) (Factory set: On) The contents of the address setting switch set the COOL/ Terminal block for transmission HEAT address, demand..

- Page 222 Adaptors for Connection of Air Conditioners Si30-408 Cautions • Specifications of connecting wires Sheathed wire (2 wire) of 0.75 to 1.25 mm in size • Length of connecting wirings Be sure to observe the following limits. Not heeding so may result in the malfunction of transmission.

- Page 223 Si30-408 Adaptors for Connection of Air Conditioners 5.3.3 Field Settings 1. The contents of the various settings for unified switching of the operation mode (cool, heat, fan) are as follows. Field setting start Grouping the outdoor units by each operation mode. Setting switches cannot be (Herein after refer to as 'operation mode group').

- Page 224 Adaptors for Connection of Air Conditioners Si30-408 3. To carry out operation mode switching and demand control simultaneously You can carry out operation mode switching and demand control simultaneously by setting function switch SS1 on the adaptor to 'BOTH.' Only one address, however, can be set on the adaptor, so the 'operation mode switch unit'..

Page 225: Diii-net Expander Adaptor

DIII-NET Expander Adaptor <DTA109A51> Even though the present D-BACS controls 64 groups and 128 indoor units at maximum of VRV system by a single centralized controller, a combined use with the DIII-NET enables the control of 64 groups and 1024 indoor units at maximum.- Page 226 Adaptors for Connection of Air Conditioners Si30-408 2. The limits for wiring (i.e., Maximum distance: 1000 m, Total wiring length: 2000 m, and Maximum number of branches: 16) should be applied to each adapter unit. DIII-NET expansion adapter In the ranges of A, B, and C, wirings of 1000-m maximum distance, 2000-m total wiring length, and 16 maximum branches are enabled, respectively.

- Page 227 Si30-408 Adaptors for Connection of Air Conditioners 5.4.3 Wiring 1. Connect the power supply cable coming from this adapter to the adapter power supply connector on the outdoor unit PC board. (For details on connector No., refer to information in wiring diagrams of outdoor unit and functional unit.) 2.

- Page 228 Adaptors for Connection of Air Conditioners Si30-408 Example of Wiring for system with 10 or more outdoor units Wiring 1 unit 2 units 10 units Expander adapter Caution Each range of A and B is individually subject to restrictions on the connection wiring length. (Refer to information in section “Wiring”.) Appendix..

Page 229: Versatile Usage

Si30-408 Adaptors for Connection of Air Conditioners Versatile Usage Versatile Usage 1. Diversification of risk of centralized control system The DIII-NET extended adapter is originally designed to extend the system. In this connection, according to the usage shown in figure below, it is possible to design the centralized control system so that the system risk will be diversified.- Page 230 Adaptors for Connection of Air Conditioners Si30-408 2. Relaxation of restrictions on branching DIII-NET With the DIII-NET adapter, no secondary branching is enabled. Using expander adapters, however, enables branching shown in figure below. (Direct branching from the main line is referred to as the primary branching, and further branching from the primary branching is referred to as the secondary branching.) If the expander adapter is used..

- Page 231 Si30-408 Adaptors for Connection of Air Conditioners 3. Method of extending system Using two units of expander adapters enables the connection of a maximum of 30 outdoor units (of 300 HP or less). An example of connection is shown in figure below. Note: If additional extended adapters should be installed due to expansion or else after wires are connected as shown below, a significant change of the wiring within the system will be needed.

Page 232: How To Replace The Compressor

How to replace the Compressor Si30-408 6. How to replace the Compressor For RSXYP to M: (1) Collect the refrigerant by using refrigerant Suction pipe recovery unit. (Since the setting on outdoor unit PCB is required for refrigerant recovery, refer to the warning plate Discharge pipe 'Precautions in service work'..Page 233: Hrv-related

Si30-408 HRV-Related 7. HRV-Related Group Interlock Control 7.1.1 Single-group Interlocked Operation (Basic Pattern) Purposes and The remote controller for indoor unit can control the interlocked operation with the HRV unit, and it can make an initial setting of the ventilation flow rate, the ventilation mode changeover Functions and fresh-up operation.- Page 234 HRV-Related Si30-408 7.1.2 Single-group Interlocked Operation (Direct Duct Connection) Purposes and The operation of HRV unit is interlocked to the indoor unit connected by the duct, which has a fresh air intake. Functions It can reduce the number of outlets for supply air. The HRV unit cannot be operated independently to prevent a reverse stream of fresh air to the suction side of the indoor unit, unless the fan of indoor is in operation.